Behind the scenes of Oxy’Pharm’s after-sales service, Sébastien L. has been ensuring the proper functioning of equipment since June 2020. With method and expertise, he makes sure damaged equipment gets a second life. Passionate about his job, he gives us a glimpse into his daily life, where every malfunction is a puzzle to solve.

Oxy’Pharm’s customer service team is small: one and a half people, to be precise. While this might seem surprising, efficiency is paramount. “We have one person handling administrative work and another dedicated to technical support,” explains Sébastien.

The technical support is divided into two main tasks:

- Device repairs: Sébastien receives equipment directly at the headquarters for repairs within France. Whether it’s equipment being sent back or shipped directly from the client, time is of the essence. “For items under warranty, we repair within 48 hours; for items out of warranty, it takes around 5 days.”

- Continuous assistance: Sébastien also provides ongoing support to resellers and distributors, with whom he maintains a strong partnership. “It’s like continuous training: we help with troubleshooting and are always in touch.”

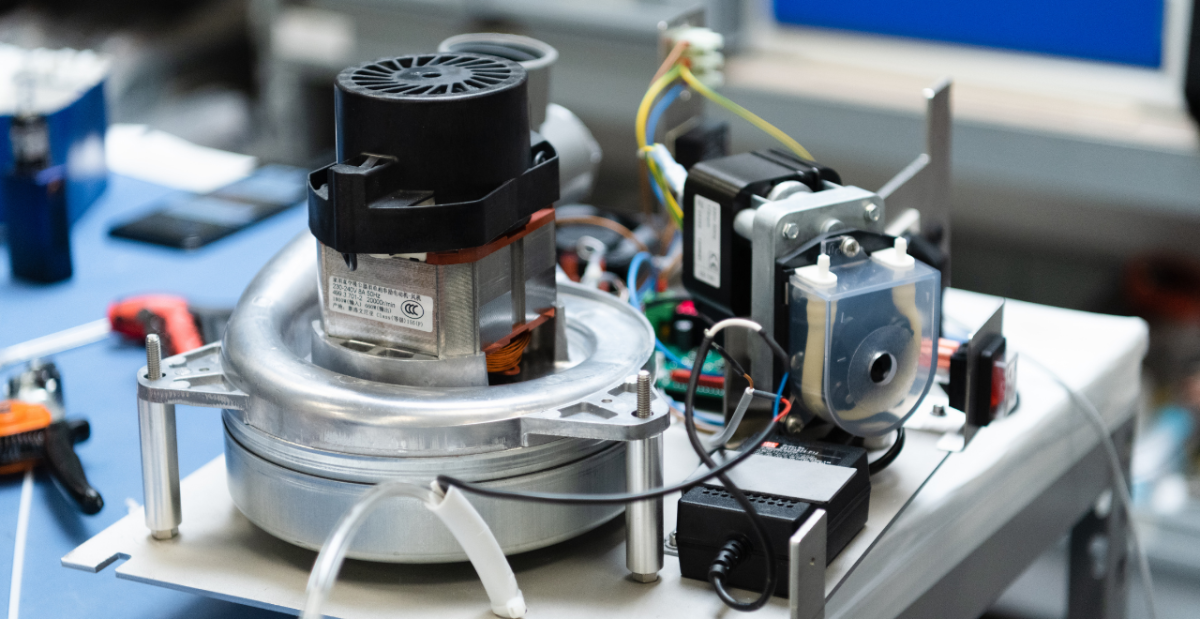

Each device has its own story, and repairs vary depending on the machine. The repair time for devices differs based on the type of equipment. “The Nocospray is fairly easy to diagnose, usually taking less than an hour to identify and fix the issue,” notes Sébastien. However, devices like the Glosair often present more complex challenges: “There can be up to 50 symptoms for the same malfunction. So, we have to proceed by elimination, and depending on the part that needs replacing, we might have to disassemble the whole thing. It can take between 4 and 6 hours to get the device back in working order.”

In addition to his technical skills, Sébastien finds great satisfaction in solving complex problems. “What I enjoy most is problem-solving,” he confides. “Whether it’s a technical or theoretical issue, I love providing a simple and educational solution. I always try to adapt my explanation so that the client fully understands, because, in the end, it’s in their best interest.”

The repair process is a well-orchestrated routine. Handling damaged devices is guided by a structured process that starts as soon as the equipment arrives. Sébastien outlines the steps: “For items under warranty, we start by identifying the problem as soon as the device arrives and proceed directly with the repair. Constant communication is maintained with the client throughout the process.” For devices out of warranty, a diagnosis is made, and a quote is provided before any repairs begin. “Once the quote is approved by the client, we have a 48-hour turnaround to repair the device and send it back,” he adds.

When asked if he repairs all Oxy’Pharm devices, Sébastien smiles. “All except for the Sanivap. They have their own customer service team and expertise. We stick to Oxy’Pharm’s product range.” Even though he doesn’t travel for repairs, Sébastien ensures smooth communication with his clients. His work isn’t limited to just the technical aspects. “Human interaction is very important,” he explains. “I feel comfortable in this job. I like adapting to the person I’m talking to and explaining issues simply, so everything is clear.”

The customer service team handles around 200 device repairs per year. Since his arrival, Sébastien estimates he’s repaired around 800 devices. Among the many machines he’s worked on, he has a particular fondness for the Alphaclean. “It’s always an interesting challenge. When you open the machine, everything makes sense. The diagnosis is logical, the symptoms are coherent, and it’s almost a pleasure to figure out what’s wrong.”

This enthusiasm shines through in his daily work. Every problem solved is a small victory, and Sébastien always takes the time to appreciate the end result. He recalls an anecdote that particularly amused him when he received a faulty Nocospray. “I contacted the client to learn more about the issue, and they replied, ‘Yes, we’re having trouble with our cocotte,’” Sébastien says with a smile. Surprised by this unexpected response, he tried to make sense of the situation, but the story didn’t end there. Shortly after, another client contacted him saying, ‘I’ve got a cocotte, and it’s broken.’ Amused by the repeated use of this unusual term, Sébastien later discovered that it was, in fact, a vocabulary mistake, behind which lay a more typical malfunction.

But no matter the complexity of the situation, Sébastien always keeps the importance of his role in mind. What he wants to share with clients: “What drives me is your satisfaction.”

For him, building trust is essential, and he hopes that each client feels his commitment to them. In the end, Sébastien L. doesn’t just do technical work; he is part of a human chain where every interaction counts. His passion for his job and dedication make him a valuable asset to Oxy’Pharm and to the clients who trust him.